How Stockyard Equipment can Save You Time, Stress, and Money.

Table of ContentsSome Known Facts About Stockyard Equipment.Examine This Report on Stockyard EquipmentIndicators on Stockyard Equipment You Need To KnowMore About Stockyard EquipmentThe Single Strategy To Use For Stockyard Equipment

"Toward the end of the period, we literally run that tripper every 30 or 40 minutes, inching it down the line to cover the pile off so there are no pockets for the snow and ice to enter into over the winter season," he says. "Tripper conveyors are obtaining more usual as well as with this fuel situation, we'll be seeing more of them in the market," states Simniok.

At 580-feet (177m), our tripper conveyor is among the lengthiest in the region as well as is definitely among the highest, since of the website we have to collaborate with. I see this system remaining in location permanently, as well as we are thinking of setting up another to handle our sand product.

The FS is exceptional at holding a buffer of material within the hopper enabling a regulated circulation of product to the primary conveyor belt. With fully speed adjustable belts the feeder stacker series gets rid of the requirement for a separate feeder as well as stockpiler system. The FS-Series has plenty of choices offered from tipping grids, vibrating grids to overband magnets.

The flexibility and durable design of the FS-Series allows this certain product to be as comfortable in the dock as it is on the rough atmosphere of the quarry. Side Innovate aims to locate cutting-edge means to stay one action ahead. In the very first quarter of the year, it introduced the new patent pending LTS Collection.

Stockyard Equipment Can Be Fun For Everyone

This makes it possible for the operator to position the tracks alongside the vessel, allowing the stockpiler to travel along the side of the vessel without the requirement to readjust the positioning of the device. This option still only needs one operator to run a whole stacker that will offer up to 1,000 tph (tonnes per hour) for continuous loading.

Duro Felguera Team goes back to 1858, when its owner Pedro Duro Benito, began Duro y Compaa. Its major tasks were based on the manufacturing of iron as well as steel, as well as in the coal mining market. By the end of the 19th century it had come to be the major iron and steel producer in Spain.

Nevertheless, what is required currently is a seamless integration of all subsystems and also a total optimization from the mine to the market. An incorporating device is called for to lessen the effort needed for all action in the product circulation chain, like product handling, storage and handling. This tool ought to build user interfaces and also communication between the different levels from the order fulfillment in the ERP system completely via to the basis procedure on the heap or even in the mine or the plant.

About Stockyard Equipment

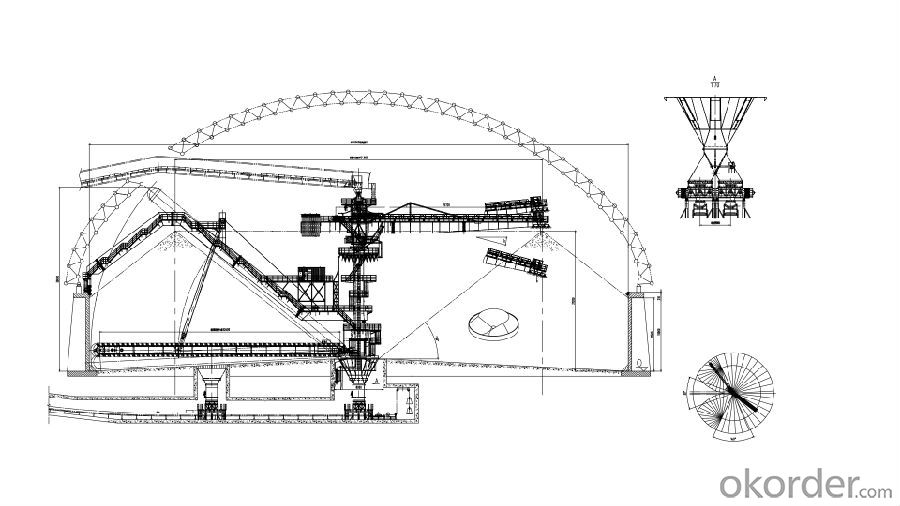

The data source offers details concerning the material top quality in the transport as well as stockpile models that monitor the material flow online. The essential input for the version is supplied by laser scanners and also positioning systems mounted on the stockyard equipments. This enables autonomous procedure of the machines. The scanners can supply surface details which will be made use of to recalculate the design.

The component materials details about the material on the more accumulation as well as its form, in addition to its various residential properties (high quality). Product distribution on the stockpile will be determined with a computational module based on the info from the modules Material Tracking, Stacking and Reclaiming Technologies and the results of the 3D laser scanning.

The visualization shows an introduction of all accumulations on duty site. The stockyard can be presented in 2D or in 3D. For an in-depth analysis of the stockyard, it is possible to zoom and readjust the angle of the view. The sight can be readjusted from different point of views and separate stacks which can be divided right into tiny specific digital heaps that can be picked separately.

In 2010 bulk product handling accounted for 3. 3 billion tonnes of the seaborne trades. Whether it is an export or import terminal, a stockyard is one of the basic aspects of a completely dry bulk terminal where a variety of taking care of equipment is deployed; on top of that, it is frequently a critical stock and also it is constantly an essential component in the overall terminal logistic efficiency.

All About Stockyard Equipment

For a stockyard analysis numerous elements need to be taken into account, such as: the product residential properties of the products dealt with at the terminal; the strength of the ground conditions; devices constraints (e.

Open storage open up are common for materials like coal, aggregates, accumulations iron and also. Certain generally utilized storage space methods might not work for all bulk materials.

Stockyard Equipment for Dummies

For a receptacle, the cone angle is affected by the wall rubbing angle and the effective angle of interior friction. Consequently, the cone angle article source influences the minimal opening of the hopper and its discharging capacity. Devices features as well as stacking technique The tools that need to be thought about for a stockyard analysis research study is not restricted to the real storage space options (e.